According to a report from the ‘Science and Technology Daily,’ researchers from Northeastern University in the United States have verified the potential use of sputtering technology in the production of large-area two-dimensional van der Waals materials. Using this technology, they have manufactured and identified a highly promising material – niobium telluride, which has an ultra-low melting point of approximately 447°C (starting temperature). This achievement has been published in the recent issue of the ‘Advanced Materials journal‘.

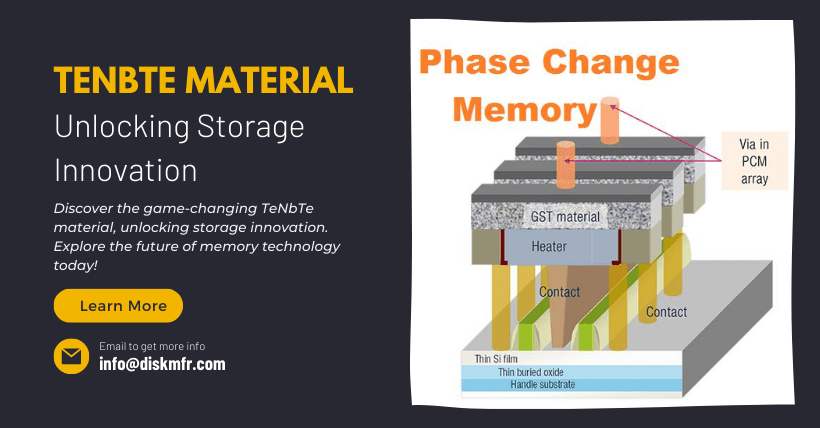

Phase-change memory is a non-volatile storage device that utilizes the ability of phase-change materials to transition from an amorphous state (disordered atomic arrangement) to a crystalline state (atoms densely packed together). This transformation results in reversible electrical characteristics that can be used for data storage (Long-Term Data Storage: Best Options Compared | DiskMFR) and retrieval. In recent years, two-dimensional van der Waals transition metal dichalcogenides have emerged as promising phase-change materials for phase-change memory.

Although still in its early stages, phase-change memory holds the potential to revolutionize data storage due to its high storage density and faster read/write capabilities. However, the complex switching mechanisms and manufacturing methods associated with these materials still pose challenges for large-scale production.

Researchers indicate that sputtering is a widely used technique involving the deposition of thin films of materials onto substrates, allowing for precise control of film thickness and composition. In this new study, niobium telluride thin films were deposited using sputtering and initially existed in an amorphous state. However, annealing at temperatures above 272°C resulted in the crystallization of the films into a two-dimensional layered crystalline phase.

Unlike traditional amorphous phase-change materials, niobium telluride exhibits a low melting point and high crystallization temperature. This unique combination reduces the reset energy and enhances the thermal stability of the amorphous phase. Researchers evaluated the switching performance of niobium telluride, and it showed significantly reduced operating energy compared to conventional phase-change compounds.

The team anticipates that the new material can retain data for 10 years at temperatures as high as 135°C, surpassing the 85°C limit of traditional amorphous phase-change materials. This demonstrates the excellent thermal stability of niobium telluride and its potential for use in high-temperature environments such as the automotive industry. Additionally, niobium telluride exhibits a fast switching speed of approximately 30 nanoseconds, further highlighting its potential as the next-generation phase-change memory technology.

1. This article is compiled from online sources. If there is any infringement, please contact us for removal.

2. The published content represents the views of the author and not the position of DiskMFR.

3. Related Reading: Unleashing Distributed Storage Systems in the Digital Age

4. Related Reading: Future of Energy: AI Unleashes Superior Battery Materials

5. Related Reading: Understanding the Conductivity of Semiconductor Materials

6. Related Reading: Discover PCM: The Future of Storage Beyond DRAM & NAND

7. Related Reading: Phase-Change Memory: Where DRAM Meets NAND

8. Related Reading: Extracting Rare Earth from Old Hard Drives: WD & Microsoft

9. Related Reading: Understanding Optical Clarity in Semiconductor Films

10. Related Reading: Common Crystal Oscillator Packaging Types Explained

11. Related Reading: How Polarization Impacts Wafer Electroplating Process?