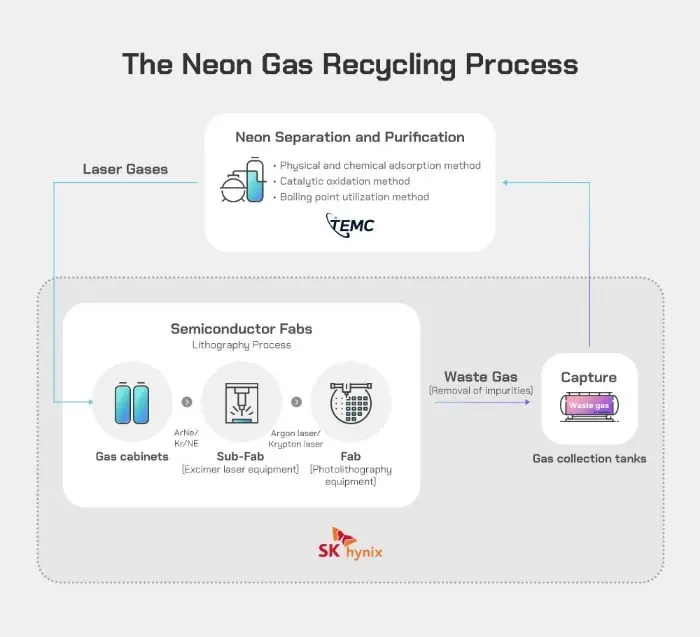

SK Hynix announced its collaboration with South Korean specialty gas company TEMC to develop the semiconductor industry’s first neon gas recovery technology.

Neon gas is one of the rare gases and is a major component of the excimer laser gas used in semiconductor lithography processes. When used as a laser light source, it has the characteristic of not undergoing chemical decomposition or change. This means that once neon is used, it can be recycled after impurities are removed through separation and purification processes.

In this regard, SK Hynix and TEMC have successfully developed neon gas recovery technology. These companies collect neon gas in collection tanks, which would otherwise be emitted into the air through scrubbers after the lithography process. Then, through TEMC’s gas treatment process, the neon gas is selectively separated and purified.

The purified neon gas will be recycled back to SK Hynix for further use in semiconductor manufacturing processes. Currently, the neon gas recovery rate is 72.7%. SK Hynix plans to continuously improve the purification rate to increase the neon gas recovery rate to 77%.

Applying neon gas recovery technology in semiconductor factories is expected to reduce neon gas procurement costs by about 40 billion Korean won per year. This technology is also expected to reduce greenhouse gas emissions from neon gas production by about 12,000 tons of carbon dioxide equivalent per year.

Disclaimer: This article is created by the original author. The content of the article represents their personal opinions. Our reposting is for sharing and discussion purposes only and does not imply our endorsement or agreement. If you have any objections, please contact us through the provided channels.