Common Crystal Oscillator Packaging Technologies and Their Characteristics

01

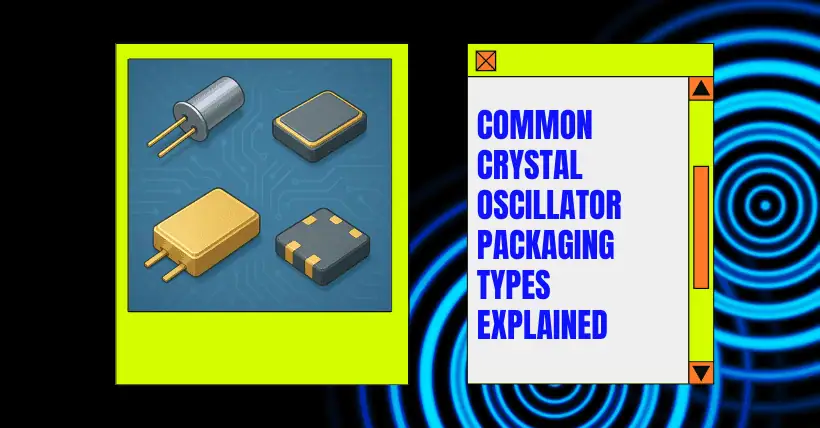

Metal Can Packaging

Metal can packaging is considered the “sturdy guardian” of the crystal oscillator packaging world. It uses metal materials with excellent electrical and thermal conductivity, such as stainless steel or copper alloys, to tightly encase the crystal oscillator chip. This packaging method offers significant advantages, with strong shielding capabilities that effectively resist external electromagnetic interference—like putting an “electromagnetic protective suit” on the crystal oscillator—allowing it to operate stably even in complex electromagnetic environments.

02

Plastic Packaging

Plastic packaging holds a place in the electronics market due to its low cost and simple manufacturing process. Through injection molding and similar techniques, it uses plastic materials (such as epoxy resin or phenolic resin) to encapsulate the crystal oscillator chip. Plastic-packaged oscillators offer high design flexibility in appearance and can be made in various shapes and sizes according to different needs, making them widely used in consumer electronics such as smartphones and tablets.

03

Ceramic Packaging

Ceramic packaging is like the “high-end custom model” of crystal oscillators. It uses ceramic materials as the package shell and seals the crystal oscillator chip through high-temperature sintering and other complex processes. Ceramic materials provide excellent electrical and physical properties, giving ceramic-packaged oscillators extremely high stability and reliability. They maintain good performance even in extreme environments such as high temperature and high frequency.

04

Surface-Mount Device (SMD) Packaging

Surface-mount device (SMD) packaging is the “favorite” driven by the trends of miniaturization and automated production in electronics. It directly solders the crystal oscillator onto the surface pads of a printed circuit board (PCB), achieving electrical connection and mechanical fixation through surface-mount processes like reflow soldering.

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.