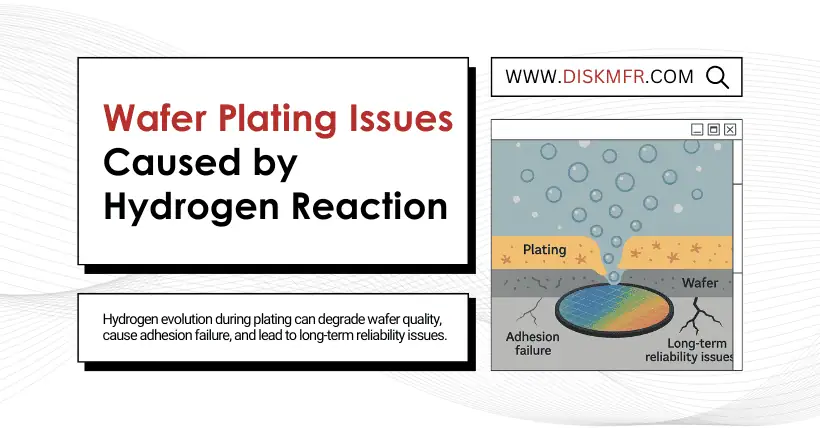

Previously, we introduced side reactions on the wafer surface—specifically, the hydrogen evolution reaction, which refers to the release of hydrogen gas. When the cathode (wafer) current efficiency decreases, hydrogen evolution has many adverse effects.

Hydrogen embrittlement:

When the hydrogen evolution reaction occurs, some hydrogen atoms do not escape directly but instead diffuse into the metal or silicon substrate lattice. Because hydrogen atoms are extremely small, they can easily enter lattice defects, dislocations, or grain boundaries of metals or silicon. These hydrogen atoms cause local lattice expansion, distortion, and even residual stress. Over time, this leads to coating embrittlement and reduced strength.

Formation of pinholes and pits:

Pinholes are small through-holes, while pits are small surface depressions. During the early stage of coating deposition, if hydrogen bubbles adhere to the wafer surface and do not detach in time, metal will deposit around the bubbles. Once the bubbles later disappear, they leave behind small through-holes, forming pinhole defects with a “comet tail-like” structure under the microscope.

Coating “burning”:

“Burning” refers to the appearance of loose, porous, blackened, and rough deposits on the electroplated layer, making it look as if it were “burned” and severely degrading the coating quality. After large amounts of H⁺ are reduced to hydrogen gas on the wafer surface, the OH⁻ concentration in those areas rises rapidly, creating an alkaline environment. Metal ions (such as Cu²⁺, Ni²⁺) easily form hydroxide precipitates. These non-metallic deposits co-deposit with metal, leading to loose grains, many voids, and a darkened appearance.

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.