The semiconductor chip is often likened to the “root” of the information industry, while the photolithography machine used to manufacture the chip is also known as the “engine” driving the advancement of the information industry. Without the photolithography machine, the semiconductor industry would face a chain-breaking crisis, and Moore’s Law would stand a standstill.

✅ ASML lifts restrictions with 600 lithography machines

ASML has been dissatisfied with the agreements made by the US and Japan to restrict the export of chip production equipment to China. However, ASML has found many ways to circumvent these agreements.

China has been ASML’s primary market, as it accounts for over 20% of the world’s chip demand, which has driven the demand for chip production equipment. ASML has a close working relationship with relevant Chinese enterprises, and therefore, cannot fully comply with the US’s restrictions on chip equipment.

There is currently an online discussion about ASML lifting restrictions with 600 lithography machines, for 16 billion yuan. Foreign media reports suggest that this is equivalent to a “showdown”. What’s going on?

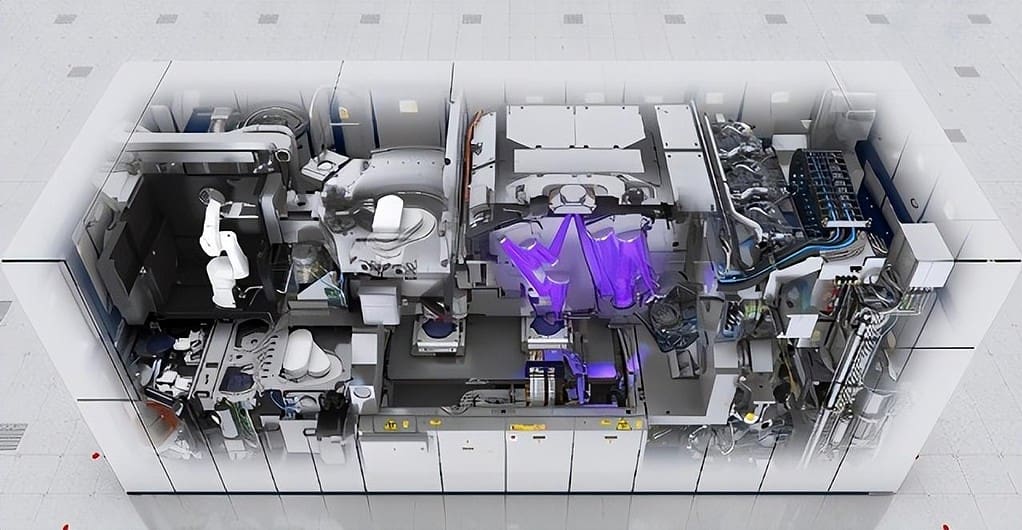

ASML’s chip production equipment has now entered a new level. Its advanced High NA EUV lithography machine has already entered the research and production phase and is expected to create another market craze.

However, there are still many obstacles to the future production of this new machine, including the huge R&D costs involved. Currently, ASML is still struggling to raise funds for the project, and its senior executives have stated that the company needs to maintain its normal business operations to achieve its future High NA EUV production plan.

Despite this, ASML has no intention of complying with the US’s related agreements. It has made corresponding market arrangements during this time, which can be seen as a “showdown” with the US.

✅ ASML: Not Giving Up on the Chinese Market

As we all know, chip manufacturing cannot be achieved without photolithography machines. Despite being under pressure from the US recently, ASML has been increasing its shipment capacity to the Chinese market. For example, in the first quarter of this year, ASML shipped 23 DUV photolithography machines to China, surpassing the United States and becoming ASML’s third-largest market.

Currently, ASML not only refuses to tighten its shipment scope for DUV photolithography machines but also plans to invest NT$30 billion in expanding production in Taiwan Province, and China. With the increase in advanced photolithography machine capacity and the launch of high-NA EUV photolithography machines, ASML is expected to ship more advanced equipment freely.

According to reports, ASML made this decision for several reasons:

Firstly, the domestic market is the largest consumer market for chips. Currently, many domestic manufacturers have started to independently research and produce chips, leading to a noticeable decline in imported chips. With an increasing number of chips produced domestically, more photolithography machines and other equipment will be needed.

In addition, new energy vehicles are undoubtedly one of the future trends, and China is the largest consumer and exporter of new energy vehicles. The production and manufacturing of new energy vehicles require a large number of chips.

Compared to the smartphone industry, the automotive industry has a larger supply chain, and there will be more automotive chips produced domestically, which will naturally further increase the demand for lithography machines.

Secondly, ASML can ship more because its lithography manufacturing technology is the most advanced, and other manufacturers simply cannot replace it. It is understood that ASML’s lithography technology comes from more than 40 countries worldwide and hundreds of suppliers, and even the United States cannot independently manufacture lithography machines.

In addition, the proportion of US technology in ASML’s lithography machines is limited. Therefore, the US rule changes limiting shipments have a relatively limited impact on ASML’s lithography machine shipments. Moreover, domestic manufacturers have made many breakthroughs in advanced lithography machines, currently holding 80% of the domestic lithography machine market and 40% of the global packaging lithography machine market.

Therefore, it can be seen that ASML’s decision not to give up the Chinese market is correct.

Related:

- G-line, I-line, DUV, EUV: Key Lithography Terms Explained

- ASML Announces Beijing Repair Center After 2025

- ASML Statement: 2 Photolithography Licenses Cancelled

- ASML Targets 0.2nm Tech with Super NA Lithography by 2036!

- Leading 2nm EUV Device by ASML: Twinscan NXE: 3800E

- Global Media on ASML: Unforeseen Changes Ahead!

- ASML Earnings Miss Sparks Semiconductor Stock Plunge

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.