In recent times, Intel has made significant progress in the field of chip manufacturing.

On December 21, Intel received a new high-NA EUV lithography machine (Figure 1) delivered by the Dutch company ASML. This lithography machine can be used to manufacture 2-nanometer chips. Intel expects to officially start mass production of commercially available chips using the 2-nanometer process in 2025.

Good news arrived again on December 26. The Israeli government announced a $3.2 billion funding allocation to Intel as a subsidy for the construction of a new chip factory project (Fab 38) in the southern part of the country, with an estimated total cost of about $25 billion.

The planned Fab 38 facility is located approximately 42 kilometers from the Gaza Strip, in the Kiryat Gat area, known as the ‘Second Silicon Valley,’ adjacent to Intel’s existing wafer fabrication plant. It is expected that this facility will commence operations in 2028, and construction has already begun.

Intel has been deeply rooted in Israel for many years, establishing an office in the country in 1974. Currently, it operates four research and manufacturing bases in Israel, employing around 12,000 individuals, accounting for slightly less than 10% of the company’s global workforce.

WiFi-supporting Centrino chips and some processors were developed in Israel. In 2017, Intel also invested $15.3 billion to acquire Mobileye, an Israeli autonomous driving technology company.

It’s worth noting that this isn’t Intel’s first time receiving funding from the Israeli government. Over the past nearly 50 years, Intel has received approximately $2 billion in cumulative funding.

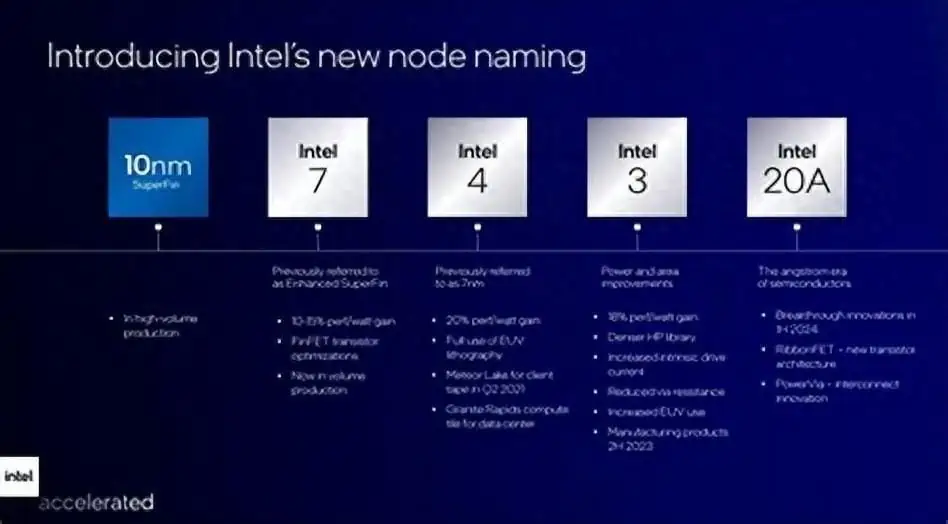

In 2021, shortly after assuming the position of CEO at Intel, Pat Gelsinger initiated significant reforms within the company, focusing on achieving breakthroughs in chip manufacturing to surpass competitors like TSMC and Samsung.

Simultaneously, Intel launched the IDM 2.0 plan, intending to establish more chip manufacturing plants across the three major continents globally, aiming to regain its dominant position in the chip manufacturing domain. The ongoing construction of the new Fab 38 factory in Israel is just a part of Intel’s ambitious plan.

Regarding the Fab 38 new factory, Intel stated, ‘The project is an important component of Intel’s efforts to create a more resilient global semiconductor supply chain. Additionally, we are planning for more manufacturing investments in Europe and the United States. The support provided by the Israeli government ensures that Israel remains a hub for global semiconductor technology and talent.’

Previously, Intel claimed breakthroughs in the 2-nanometer chip manufacturing process (also actively advancing the 1.8-nanometer process) and plans to commence commercial production by 2025.

Recent acquisitions of the latest lithography machines indicate Intel’s active involvement in the field of artificial intelligence, challenging NVIDIA by integrating AI units into consumer-grade processors.

Considering these indications, Intel is overall moving in a positive direction. It is anticipated that in the next two to three years, Intel will make a strong comeback, heralding significant changes in the existing industry landscape.