In recent years, the artificial intelligence industry has developed rapidly, with chips as its core component, receiving constant attention. However, at the Bosch Connected World 2024 conference, Tesla CEO Elon Musk expressed a view: by 2025, what may trouble the AI industry will no longer be the shortage of chips but the tension in power supply. At the same time, multiple media reports state that TSMC, a major chip foundry, is also facing electricity cost challenges. It is reported that Taiwan is considering raising TSMC’s electricity prices by up to 30%.

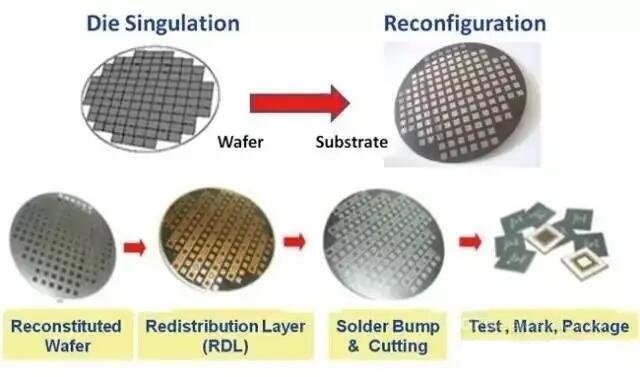

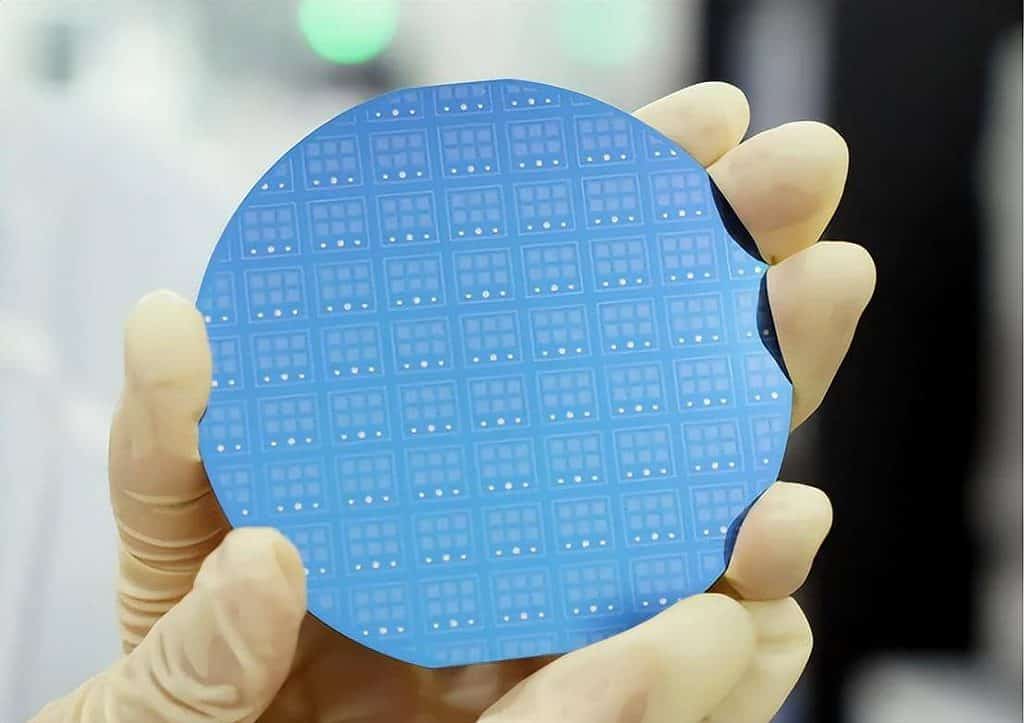

Chip manufacturing is a highly complex and energy-intensive process. From melting silicon to using high-power lasers for lithography, to creating and maintaining a vacuum state, and continuous cleaning, each link requires substantial electrical power. It is estimated that semiconductor factories consume up to 100 megawatt-hours per hour, equivalent to the electricity usage of over 80,000 North American households. This means that as the AI industry’s demand for chips continues to grow, the pressure on power supply will also increase.

With the rapid development and application of AI, discussions about its energy consumption have emerged. How much electricity does AI consume? The energy used to generate 9 photos could fully charge a smartphone.

A team composed of Hugging Face developers and researchers from Carnegie Mellon University, using a self-developed tool called Code Carbon, compared energy consumption and carbon emission data for 16 of the most popular open-source models on the HuggingFace Hub. The data shows that the electricity consumed by generative AI for every 1000 images generated ranges from 0.06 to 2.9 kilowatt-hours (kWh), with a median close to 1.35 kWh. In comparison, the energy required to charge a standard smartphone is only 0.012 kWh. This means the energy consumed to generate about nine (median) AI images is equivalent to charging a full smartphone. If users utilize the least efficient image generation model, the energy consumed to generate one image could fully charge a smartphone once, and in the worst case, even twice.

The high energy consumption implies an increase in carbon emissions.

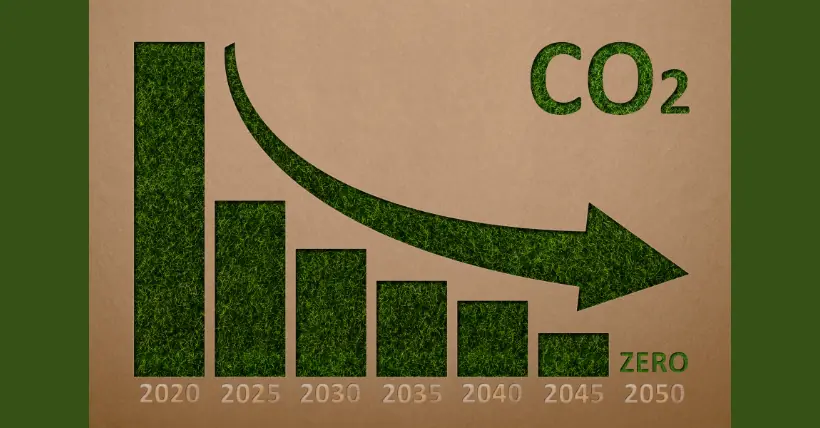

As the model size expands and the quality of generated images improves, the required energy consumption and carbon emission will further increase. The carbon dioxide emissions produced during the image generation process range from 0.1 to 0.5 grams, with outliers possibly reaching 2 grams. This means the emissions generated from producing 1000 images are equivalent to the emissions produced by a standard car traveling 6.5 kilometers.

The energy consumption and carbon emission issues in AI image generation should not be overlooked.

01

TSMC consumes 7% of the island’s electricity.

Let’s delve further into the chip industry’s electricity consumption.

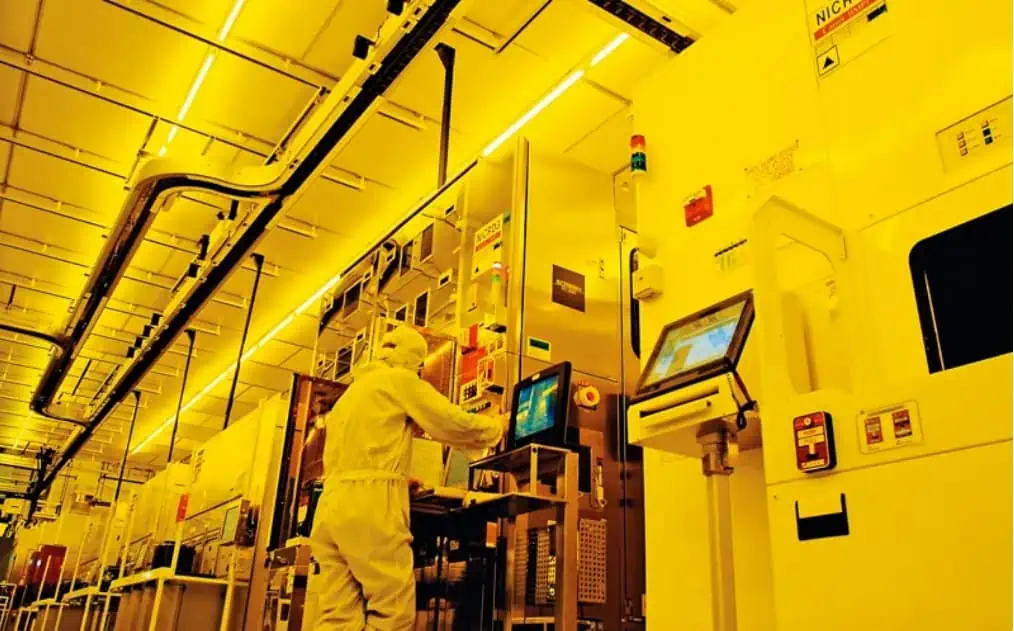

In 2020, TSMC’s EUV lithography machine consumed 10 billion kWh, accounting for over 50% of TSMC’s total electricity consumption. As TSMC continuously expands its advanced processes, it needs to keep adding lithography machines, causing an annual increase in electricity demand.

TSMC’s electricity consumption in 2020 was 16 billion kWh, approximately 5.9% of Taipower’s sales volume; in 2021, it rapidly grew to 19.19 billion kWh, accounting for 7.2% of Taipower’s sales, with a growth rate of 20%, surpassing the electricity usage of Taipei City with over 2.7 million people. Deloitte predicts that by 2025, TSMC alone will account for 12.5% of Taiwan’s total energy consumption.

Additionally, wafer manufacturing requires an ultra-clean production environment, with the entire cleanroom needing cooling and constant temperature control around 22°C. The normal operation of the cleanroom consumes a massive amount of electricity daily; to heat-treat equipment and ion devices for handling high temperatures during the chip manufacturing process, the power consumption involved is also extremely significant. Deloitte estimates that by 2028, TSMC’s electricity consumption in Taiwan could reach an astonishing 15%.

With global climate change and energy transition advancing, the stability of power supply has become a global issue. Facing such enormous electricity consumption, the biggest problem for the chip industry is that unstable power supply directly affects factory output. This is especially prominent in developing countries where insufficient and unstable power supply is a significant concern. Previously, Intel suspended its investment plans in Vietnam due to “concerns about the stability of Vietnam’s electricity supply.”

In this context, if the AI industry continues to develop at the current rate of energy consumption, the issue of tight power supply could become a bottleneck restricting its growth. Furthermore, tight power supply may pose challenges to the sustainable development of the AI industry. As attention to environmental protection and sustainable development grows, more enterprises and countries are prioritizing green energy. However, if the AI industry’s energy consumption continues to increase, the demand for green energy will also grow, potentially tightening the supply of green energy and affecting the industry’s sustainable development.

02

Without electricity, there are no chips.

Back to TSMC’s electricity consumption, just the consumption in TSMC’s factories in Taiwan is so immense, let alone the global wafer factories’ consumption scale. There are many reasons for the high electricity consumption of wafer factories, and the most direct one is that without electricity, chips cannot be produced.

More specifically, the chip industry has slightly stringent requirements for electricity use.

In terms of electricity characteristics, TSMC requires 24-hour continuous processes, belonging to full-time electricity use, with an annual load rate of 80%~90%. Particularly in advanced process capacity, it’s likely to be at full load, and the daily electricity usage curve of the production factory is likely to maintain peak electricity use throughout the day. Also, as processes are updated and production expands, TSMC’s electricity consumption will increase.

To ensure a stable power supply for TSMC, Taipower has supporting power supply measures in Hsinchu Science Park, Central Science Park, and Southern Science Park. Hsinchu has round-the-clock power plants and offshore photovoltaic support; Central Science Park is supported by Taichung power plants and offshore wind power, and without offshore wind power in the south, Southern Science Park relies mainly on Taipower’s Hsingta power plant. The concept is that Taipower’s power plants directly support TSMC-related science parks, providing dual insurance with dual circuits to prevent power outages, and ensuring uninterrupted production at TSMC. Even in case of accidents, TSMC has its backup power generation equipment.

Such high electricity consumption, for chip enterprises, underscores the growing demand for low carbon. To be greener, the chip industry has explored various measures. Actions the chip industry can take include improving energy efficiency and speed in manufacturing processes other than the current chip manufacturing process: for example, LEED-certified buildings, a technology the industry has been using for the past decade to enhance sustainability. The LEED system from the U.S. is an international green building certification system.

Of course, the most important aspect remains the use of green power. According to Deloitte, renewable energy could reduce the industry’s wafer factory energy intensity (watt-hours/dollar) from nearly 240 in 2020 to 219 in 2022, expected to drop to 206 by 2024. Moreover, the proportion of renewable energy use is expected to rise faster than the rate of reduction in energy intensity: by 2024, renewable energy is expected to constitute 28% of the energy mix, double that of 2020.

Ultimately, electricity and energy issues are environmental topics. More and more companies are bringing their environmental “KPIs” to the forefront. In April 2022, Intel announced its commitment to achieving net-zero greenhouse gas emissions; by 2030, it aims to reduce its supply chain greenhouse gas emissions by 30% compared to the emissions without investment and action; it also aims to enhance energy efficiency and reduce the carbon footprint of our products and platforms. TSMC states in its CSR (sustainability) report that by 2030, 100% of its non-productive electricity will be green, but only 25% of its productive electricity can use green power.

03

Environmental protection is not just about saving on electricity bills.

As technology advances and the global electronics market continues to expand, the semiconductor industry is developing at an unprecedented pace. For semiconductor enterprises, enhancing sustainability is not just a social responsibility but also a business return. In future development, semiconductor enterprises need to continually strengthen their investment and innovation in environmental protection and sustainable development to adapt to increasingly severe environmental challenges and market demands. In today’s era, where environmental protection and sustainable development are increasingly emphasized, semiconductor enterprises face unprecedented challenges and opportunities. As global awareness of green energy and environmental protection grows, the semiconductor industry’s attention to the green power content and proportion in production is increasingly scrutinized. For semiconductor companies, environmental awareness is not just a social responsibility but also a business return. Enhancing sustainability not only aids in long-term development but also brings numerous practical benefits.

To achieve this goal, semiconductor enterprises can take a series of measures. First, enhance technological research and innovation to promote the development and application of green production technologies. By developing more environmentally friendly and efficient production technologies, energy consumption can be further reduced, and environmental pollution can be minimized. Secondly, establish a comprehensive green supply chain management system to ensure that every link in the supply chain meets the requirements of environmental protection and sustainable development. Additionally, enhancing employee training and awareness, and cultivating a team with environmental consciousness and sustainable development concepts, are crucial.

By reducing energy consumption and waste emissions, companies can significantly lower production costs. Moreover, as social environmental awareness rises, improving sustainability helps semiconductor companies attract and retain talent and gain more consumer trust and support. Furthermore, enhancing sustainability can reduce the vulnerability of the semiconductor supply chain, ensuring its stability and security.

In the talent competition within the semiconductor industry, environmental protection also holds a significant position. The semiconductor industry is vying for technical talent with various other industries, making a good environmental record particularly crucial, especially in attracting young employees. According to Deloitte’s 2023 survey of Generation Z and Millennials, one-sixth of respondents have already changed jobs or industries due to climate issues, with another quarter planning to do so in the future. This trend highlights the significance of environmental protection and sustainable development in the semiconductor industry’s talent recruitment.

Related:

- Is Nuclear Power the Future of Advanced AI Development?

- How Many Kilowatt-Hours Does It Take To Make a Single Chip?

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.