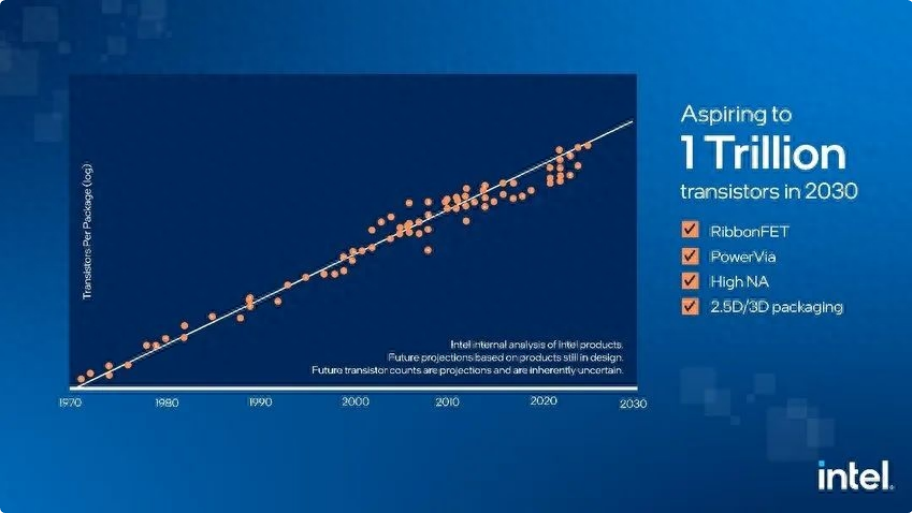

In the past half-century, the development of integrated circuits has always followed ‘Moore’s Law‘: the number of transistors contained in chips approximately doubles every 18-24 months, resulting in a doubling of chip performance and a halving of costs.

Chips have been evolving towards smaller manufacturing processes, starting from the initial 0.35 micrometers to 0.18 micrometers, 0.13 micrometers, 90 nanometers, 65 nanometers, 45 nanometers… and now to the current 5 nanometers, and 3 nanometers.

01

What is the concept of ‘nanometer’?

‘Nanometer‘ represents the size of transistors in processors and is a numerical value used to distinguish chip manufacturing processes, also known as lithography.

1 nanometer equals one-thousandth of a micrometer (1 micron), while the diameter of a human hair is approximately 100 micrometers.

What concept is this? Not to mention the naked eye, most microscopes can’t even see it. It requires the use of specialized atomic force microscopes to observe.

Even the DNA strands in the human body are 2.5 nanometers in size, yet manufacturers worldwide are competing to work within even smaller gaps.

02

Why do chip manufacturing processes keep getting smaller?

While making chips smaller in nanometer size has its advantages, it’s not without drawbacks. Firstly, the smaller the manufacturing process, the more complex the production becomes. Additionally, more minor chips are more prone to overheating. But why do manufacturers still insist on making even more minor chips?

Because smaller chips offer more pronounced advantages:

- Smaller individual transistor sizes allow for denser packing, as the small size of each transistor permits manufacturers to fit more transistors into the same-sized chip.

- With more transistors, chips can perform more calculations, making them more powerful in terms of functionality.

Additionally, as transistors get smaller, the distance between each transistor decreases. This results in faster movement of electrical signals, leading to quicker data transfer and operation speeds, as well as lower power consumption.

In 2022, Belgium’s microelectronics research center, IMEC, released a statistical chart. Over the course of 52 years since the birth of the Intel 4004 processor, the number of transistors on CPU chips has increased by a staggering factor of 100 million. Starting with just over a thousand transistors, it has evolved to the level of hundreds of billions (as seen in Apple’s M1 Ultra). Even Intel has set a goal to integrate 1 trillion transistors into a single chip by the year 2030.

As integration levels continue to rise and our transistors keep getting smaller, we are now facing one of the most crucial challenges of the 21st century:

Just how small can we manufacture transistors?

03

What is the current level of advancement in chip manufacturing processes?

According to relevant financial data, in 2022, the majority of foundry and logic production capacity still relied on process nodes of 28 nanometers and above (56.3%). The 10 nanometers and below nodes were primarily occupied by three key players: TSMC, Samsung Electronics, and Intel.

In 2021, IBM made a groundbreaking announcement, successfully developing the world’s first 2-nanometer chip manufacturing technology. This innovation allows for the placement of 500 billion transistors in a space roughly equivalent to the size of a fingernail, with each transistor being approximately the size of 5 atoms.

Last year, Samsung announced that it had begun delivering its first 3-nanometer GAA (Gate-All-Around) chips, making it the first company to commence large-scale production of 3-nanometer chips.

In response to the challenges, global semiconductor manufacturing leaders TSMC and Intel have also taken action: they are gearing up for mass production of 3-nanometer chips and have put 2-nanometer technology on their agendas. The semiconductor industry is on the brink of a fierce chip battle.

In the past few years, many have been proclaiming that Moore’s Law has become obsolete. It’s likely that even Gordon Moore himself never imagined that this law would hold true for several decades.

Al Giant (Nvidia) founder Hwang also said: that the semiconductor industry is close to the limit Transistors are almost the size of atoms

In a sense, we can keep shrinking transistors, but we cannot shrink atoms (atoms being the smallest units that make up ordinary matter, with the diameter of a typical silicon atom, a common semiconductor material, being around 0.1 nanometers.

Going from 3 nanometers to 2 nanometers, and even down to 1 nanometer, a width of 1 nanometer can only accommodate 2 silicon atoms. If we continue to shrink further, we will enter the realm of quantum physics.

Nevertheless, highly skilled technology engineers continue to work on developing more advanced manufacturing and packaging processes and searching for alternative materials to extend and surpass Moore’s Law.

The question remains: How small can we actually manufacture transistors?

Is this a matter of reaching the physical limits, or is it a challenge limited by human ingenuity?

What are your thoughts?

Related:

Disclaimer: This article was created by the original author (Xinpianxiaoluoluo). The content of the article represents their personal opinions. Our reposting is for sharing and discussion purposes only and does not imply our endorsement or agreement. If you have any objections, please contact us through the provided channels.