01

What is Wafer Mount?

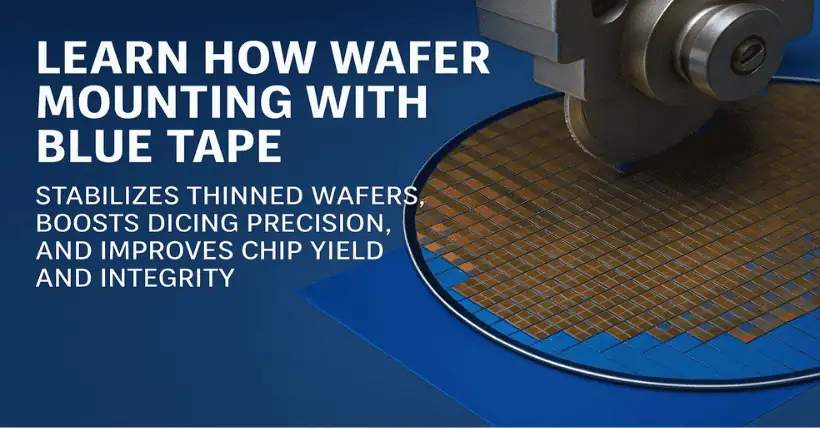

Wafer mount refers to the process of attaching a thinned wafer onto a special adhesive film, typically blue in color, commonly referred to in the industry as “blue tape.” The purpose of wafer mount is to prepare the wafer for the subsequent dicing process.

After thinning, wafers become extremely thin—usually only a few tens of micrometers thick—and are prone to cracking or warping, thus requiring support and fixation via mounting.

02

What is the Purpose of Wafer Mount?

The main purposes of wafer mount are:

- To fix the wafer: Thinned wafers are fragile. Mounting stabilizes the wafer and prevents breakage or shifting during handling and dicing.

- To assist in dicing: Blue tape has moderate adhesiveness that holds the wafer in place, enabling the dicing machine to cut each die precisely and steadily.

- To facilitate die picking: The blue tape mounted on a metal frame allows the use of automated die pickers to accurately extract each chip from the tape.

03

Detailed Process Flow of Wafer Mounting

Below is a standard wafer mounting operation flow explained step-by-step:

1. Wafer Thinning (Back Grinding)

Before mounting, wafers typically undergo thinning, reducing their thickness from several hundred micrometers to a few tens of micrometers to meet packaging requirements.

Since thinned wafers are extremely fragile, wafer mounting must be performed promptly afterward.

2. Blue Tape Preparation

Blue tape is a polymer material with medium adhesiveness and some heat resistance. Its blue color aids in optical identification.

The tape is pre-stretched and mounted on a metal ring frame, which facilitates mounting and later loading into the dicing machine.

3. Attaching the Wafer to the Blue Tape

Using a dedicated mounting machine, the thinned wafer is gently held and precisely pressed onto the center of the blue tape, ensuring the entire wafer lies flat and adheres well.

Bubbles or particles must be avoided during this process to maintain dicing quality.

4. Heat Curing (if required)

To enhance adhesion between the film and wafer, certain types of blue tape require low-temperature heating (e.g., 60~80°C) for a few minutes after mounting.

This stabilizes the film’s state and improves wafer fixation.

04

Impact of Wafer Mounting on Subsequent Processes

The quality of wafer mounting directly affects dicing and packaging yield:

- Loose adhesion or bubbles: The wafer may shift or crack during dicing, damaging chip edges.

- Excessive or insufficient adhesion: High adhesion may damage chips during die picking; low adhesion may cause chips to fly off during dicing.

Therefore, selecting the right blue tape type and controlling the mounting temperature and pressure are key to successful processing.

05

Summary

Wafer mounting, while an intermediate step in chip packaging, plays a vital role in bridging wafer thinning and dicing. It directly impacts chip integrity and yield.

Key Takeaways:

| Item | Description |

|---|---|

| Purpose | Fix the wafer, assist dicing, prevent breakage |

| Tape Features | Blue color, medium adhesiveness, thermal stability |

| Key Operations | Mount after thinning, install in frame, heat cure if needed |

| Process Impact | Affects dicing accuracy, chip integrity, yield |

Related:

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.